Understanding Exactly How Sugar Canes Work: What Are Sugar Canes Utilized For in Food and Beyond?

Sugar walking canes are indispensable to numerous facets of both culinary and commercial practices. Their versatility allows them to be changed right into sweeteners, beverages, and even biofuels. As one discovers the trip from farming to handling, the varied applications of sugar walking canes disclose a complex interplay in between agriculture and industry. The ramifications of sugar walking cane manufacturing expand past simple energy, raising inquiries regarding environmental sustainability and financial impact.

The History and Origin of Sugar Canes

Although commonly considered approved in modern diet regimens, the history and beginning of sugar walking sticks disclose a complex journey that covers countless years. Indigenous to Southeast Asia, sugar walking stick was initial cultivated around 8000 BCE, with its pleasant juice ending up being extremely valued by early people. By the initial millennium AD, it spread out to India, where it was refined right into taken shape sugar, a significant advancement that transformed its use and profession. The introduction of sugar walking stick to the Mediterranean took place around the 7th century, thanks to Arab traders, who identified its financial potential.During the Age of Expedition, European homesteaders established sugar haciendas in the Caribbean, substantially affecting worldwide profession. By the 17th century, sugar ended up being an essential product, fueling economic climates and affecting social frameworks. The tale of sugar canes is linked with farming, commerce, and cultural exchanges, noting its significance fit contemporary economic systems and culinary practices.

Growing and Gathering Practices

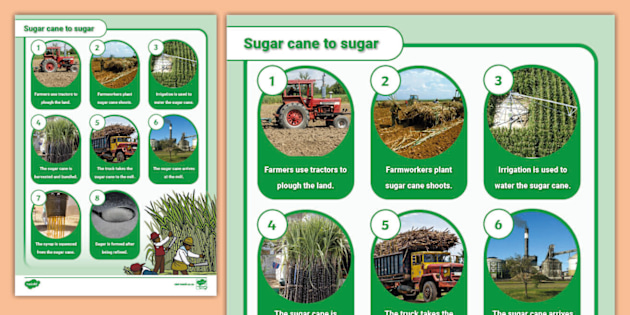

The cultivation and harvesting of sugar canes involve several critical practices that figure out the top quality and yield of the crop - What Are Sugar Canes Used For. Crucial element include reliable dirt preparation techniques, accurate growing approaches, and effective gathering strategies. Comprehending these methods is crucial for enhancing manufacturing and making sure sustainability in sugar walking stick farming

Dirt Preparation Strategies

Efficient soil prep work strategies are necessary for effective sugar cane farming, as they lay the foundation for healthy growth and suitable yield. The procedure starts with soil screening to analyze nutrient levels and pH balance, permitting customized changes. Raking and tilling are then employed to freshen the soil and damage up compaction, enhancing root infiltration. Incorporating raw material, such as garden compost or well-rotted manure, enhances soil fertility and framework. In addition, correct water drainage systems are important to avoid waterlogging, which can hinder cane growth. Cover chopping may likewise be used to reduce weeds and boost dirt health and wellness. These practices jointly guarantee that sugar walking stick has the most effective environment to grow, resulting in durable plant wellness and enhanced productivity.

Growing and Growth

Effective planting and growth techniques are important for taking full advantage of the return of sugar walking stick. The procedure starts with picking healthy and balanced seed canes, which are segments of fully grown stalks rich in buds. These seed canes are generally planted in well-prepared dirt, ideally at a deepness of 4 to 6 inches, ensuring sufficient dampness and aeration. Sugar cane grows in warm climates with enough sunshine and calls for constant watering, especially throughout completely dry spells. Fertilizing with phosphorus, nitrogen, and potassium is essential to advertise robust growth. Weed control is additionally crucial, as competitors can prevent advancement. Regular monitoring of plant wellness and dirt problems permits prompt interventions, ultimately bring about a successful crop that meets market needs.

Gathering Methods

Harvesting sugar cane needs careful preparation and implementation to assure optimal yield and quality. Usually, the harvest takes place when the walking cane reaches ideal sugar web content, often between 12 to 18 months after planting. There are 2 key methods: handbook and mechanical harvesting. Hand-operated harvesting includes laborers utilizing machetes to cut the stalks at ground level, guaranteeing marginal damage to the plant and dirt. In comparison, mechanical harvesting employs customized equipments that reduced, cut, and deliver the walking cane, raising performance and decreasing labor prices. Nevertheless, mechanical approaches can cause greater dirt compaction and loss of nutrients. Despite the technique, prompt harvesting is important, as delays can cause lowered sugar high quality and increased sensitivity to illness and pests.

Handling Methods for Sugar Extraction

The processing of sugar cane is a crucial stage in sugar production, encompassing numerous crucial techniques - What Are Sugar Canes Used For. Originally, collected cane goes through crushing and juicing to remove its pleasant liquid. This juice after that proceeds through purification and formation, changing it right into the sugar most generally utilized today

Gathering Sugar Walking Cane

Sugar walking cane gathering marks a vital stage in the production process, where timing and strategy play vital duties in taking full advantage of yield. Usually, the harvest happens when sugar web content goes to its top, which differs based on climate and growth conditions. Employees use specialized equipment or manual devices to reduce the walking stick at the base, making sure minimal damage to the plant. Correct method is important; reducing expensive can decrease the quality and quantity of the sugar drawn out later on. After reducing, the walking cane should be moved promptly to processing facilities to avoid spoilage and sugar deterioration. The effectiveness of the harvesting procedure greatly influences the overall productivity and success of sugar walking stick farming, making it an essential emphasis for producers.

Crushing and Juicing

As soon as sugar cane is harvested, the following important action entails juicing and squashing to remove the sweet liquid which contains sucrose. This process normally utilizes heavy equipment created to crush the stalks, breaking down the fibrous structure and releasing the juice. Rollers or mills apply substantial pressure, enabling the cane juice to stream out while separating the fibrous residue, recognized as bagasse. As soon as smashed, the walking cane is frequently based on a collection of pushing phases to maximize juice removal. The gathered juice is rich in sugar and may contain contaminations, which will be attended to in later handling steps. Generally, juicing and squashing are critical methods that transform gathered sugar walking cane into a fluid type suitable for more improvement.

Filtration and Crystallization

Purification and condensation are pivotal procedures in changing raw cane juice right into polished sugar. After removing juice from crushed sugar walking sticks, the liquid includes contaminations such as plant minerals, proteins, and fibers. To accomplish filtration, the juice goes through clarification, where warmth and lime are contributed to speed up pollutants, which are after that eliminated. The cleared up juice is then concentrated through dissipation to form a thick syrup.Next, condensation takes place, where sugar crystals develop as the syrup cools. This procedure typically includes seeding the syrup with existing sugar crystals to advertise consistent development. The resulting crystals are divided from the staying molasses through centrifugation, generating pure sugar. This polished product is after that dried out and packaged for different culinary uses.

Culinary Uses of Sugar Canes

While commonly associated largely with sweeteners, sugar canes use a flexible series of culinary applications past their role in sugar production. Fresh sugar walking cane can be juiced, producing a pleasant, stimulating beverage appreciated in many tropical areas. This juice acts as a base for mixed drinks and healthy smoothies, adding a distinct taste profile.Additionally, sugar cane syrup, stemmed from condensing the juice, is used as a natural sugar in different meals, from sauces to treats. The syrup passes on an abundant, caramel-like taste, enhancing both mouthwatering and wonderful recipes.In some foods, sugar cane stalks are smoked or baked, giving a distinct smoky taste that complements vegetables and meats. Sugar cane can be incorporated into desserts, such as puddings and sweets, where its sweetness and coarse texture develop delightful contrasts. In general, sugar walking canes add to both innovative and typical cooking developments throughout varied cultures.

Industrial Applications Beyond Food

Beyond their cooking uses, sugar walking canes play a significant role in different industrial applications, contributing to markets such as bioenergy, paper manufacturing, and bioplastics. The coarse material of sugar cane is used in the production of biofuels, particularly ethanol, which works as a renewable resource resource that minimizes dependence on fossil fuels. In the paper sector, bagasse, the coarse deposit left after juice extraction, is processed right into pulp for paper and cardboard manufacturing, promoting sustainable practices by making use of waste. Additionally, advancements in bioplastic innovation have actually led to visit this site right here the development of biodegradable plastics obtained from sugar walking cane, using an environmentally friendly option to standard petroleum-based plastics. These commercial applications not just enhance the value of sugar walking canes yet likewise straighten with global motions towards sustainability and eco-friendly resources, highlighting their convenience beyond the cooking area.

The Environmental Influence of Sugar Walking Stick Production

The manufacturing of sugar cane, despite its various industrial advantages, postures substantial environmental challenges. Logging is typically an effect, as substantial locations of land are cleared to grow sugar walking cane, leading to habitat loss and biodiversity decline. In addition, the intensive farming techniques connected with sugar walking stick cultivation can result in soil deterioration and erosion. The hefty use pesticides and fertilizers to optimize returns adds to water air pollution, adversely impacting marine ecosystems.Moreover, sugar walking stick manufacturing is linked to boosted greenhouse gas exhausts, especially through land-use adjustments and the burning of walking stick areas before harvest. These practices not only impact air quality but likewise add substantially to climate modification. In enhancement, the water-intensive nature of sugar walking cane farming places stress on regional water resources, affecting environments and areas reliant on these supplies. Addressing these environmental influences is important for lasting sugar cane manufacturing in the future.

Regularly Asked Inquiries

Are There Health And Wellness Conveniences Related To Consuming Sugar Cane?

The inquiry of wellness benefits related to sugar walking stick usage highlights possible advantages. Sugar walking cane might provide hydration, essential minerals, and anti-oxidants, but small amounts is essential due to its natural sugar material and possible health and wellness effects.

Just How Does Sugar Walking Stick Contrast to Various Other Sweeteners Nutritionally?

Sugar walking stick provides natural sweetness, mostly consisting of sucrose, while other sweeteners differ in structure and caloric web content. Compared to artificial options, sugar cane provides minerals and vitamins, though it remains high in calories and carbohydrates.

Can Sugar Cane Be Grown in Non-Tropical Areas?

Sugar walking cane mainly grows in exotic environments, calling for cozy temperature levels and plentiful rainfall. While some non-tropical areas attempt growing, my company success is restricted as a result of inadequate heat and expanding periods, making large-scale manufacturing testing.

What Are the Common Bugs or Conditions Affecting Sugar Canes?

Typical bugs impacting sugar canes consist of the sugarcane borer and aphids, while diseases like fallen leave scald and red rot position considerable hazards. Reliable monitoring approaches are crucial for maintaining healthy sugar walking cane plants and optimizing yields.

How Does Sugar Cane Influence Citizen Economies?

The impact of sugar walking stick on neighborhood economies is substantial, supplying employment possibilities, increasing agricultural industries, and adding to exports. Its farming sustains local businesses and improves community growth via raised earnings and infrastructure renovations. Indigenous to Southeast Asia, sugar walking stick was initial grown around 8000 BCE, with its sweet juice coming to be very valued by early civilizations. The intro of sugar cane to the Mediterranean happened around the 7th century, thanks to Arab investors, that acknowledged its economic potential.During the Age of Exploration, European homesteaders developed sugar vineyards in the Caribbean, considerably affecting worldwide profession. The processing of sugar walking stick is read this post here a vital stage in sugar production, incorporating several crucial methods. While often associated mainly with sugar, sugar canes use a functional array of cooking applications past their role in sugar production. The heavy usage of chemicals and fertilizers to make best use of yields contributes to water pollution, detrimentally impacting marine ecosystems.Moreover, sugar cane production is connected to increased greenhouse gas emissions, particularly via land-use changes and the burning of walking cane areas prior to harvest.